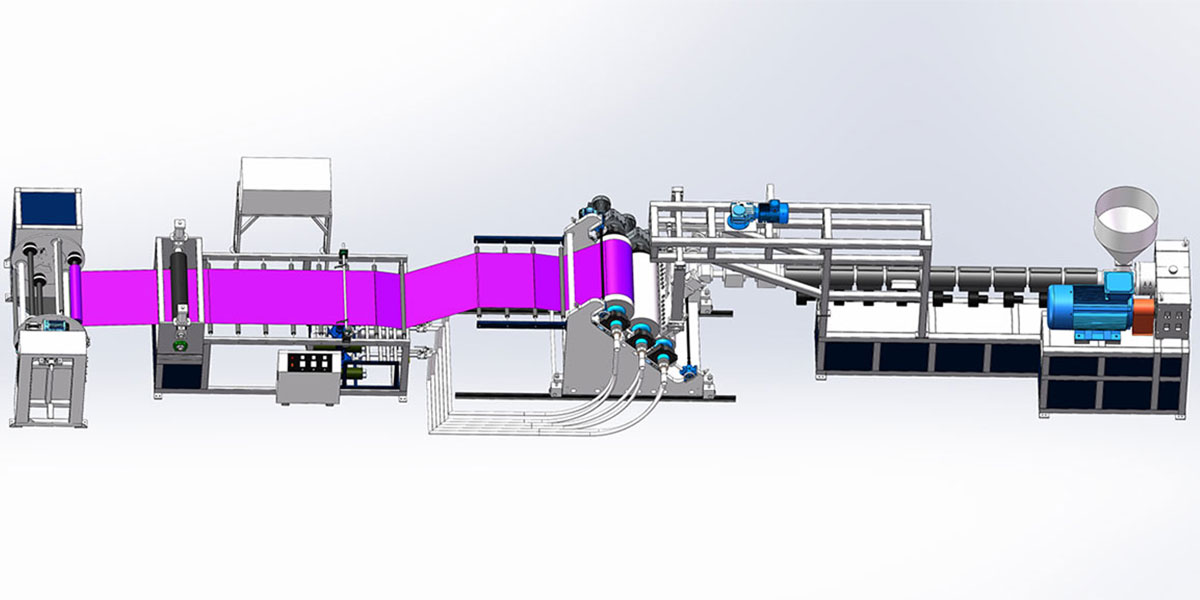

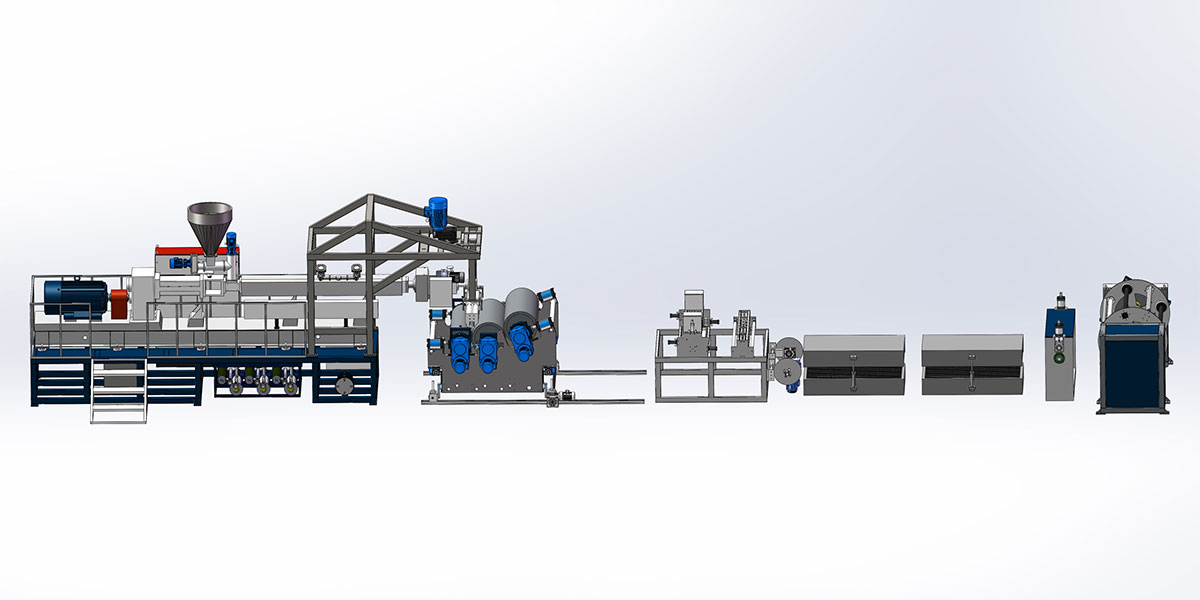

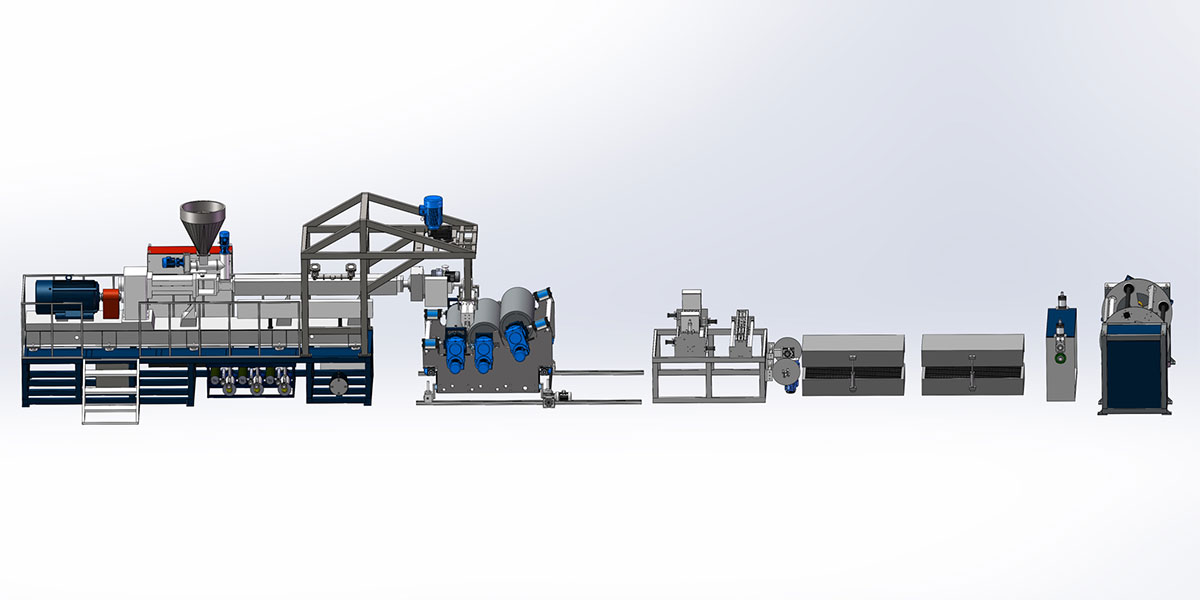

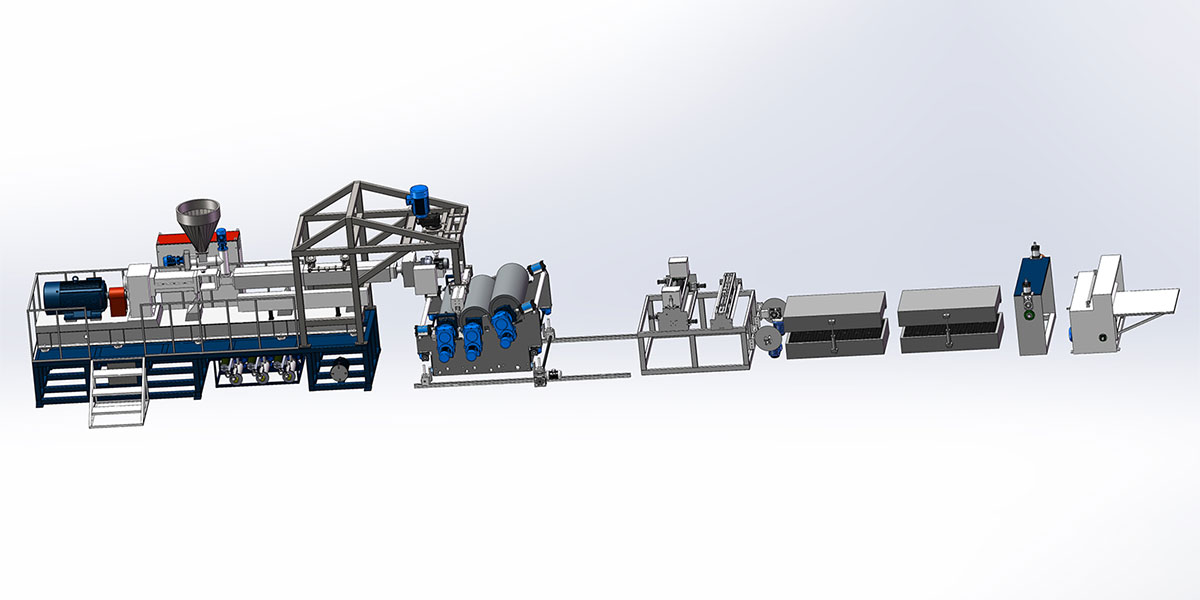

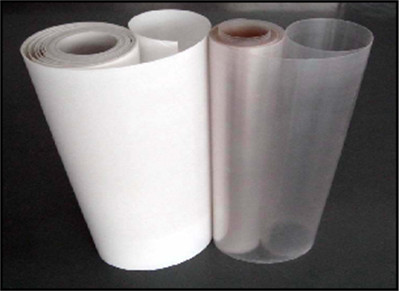

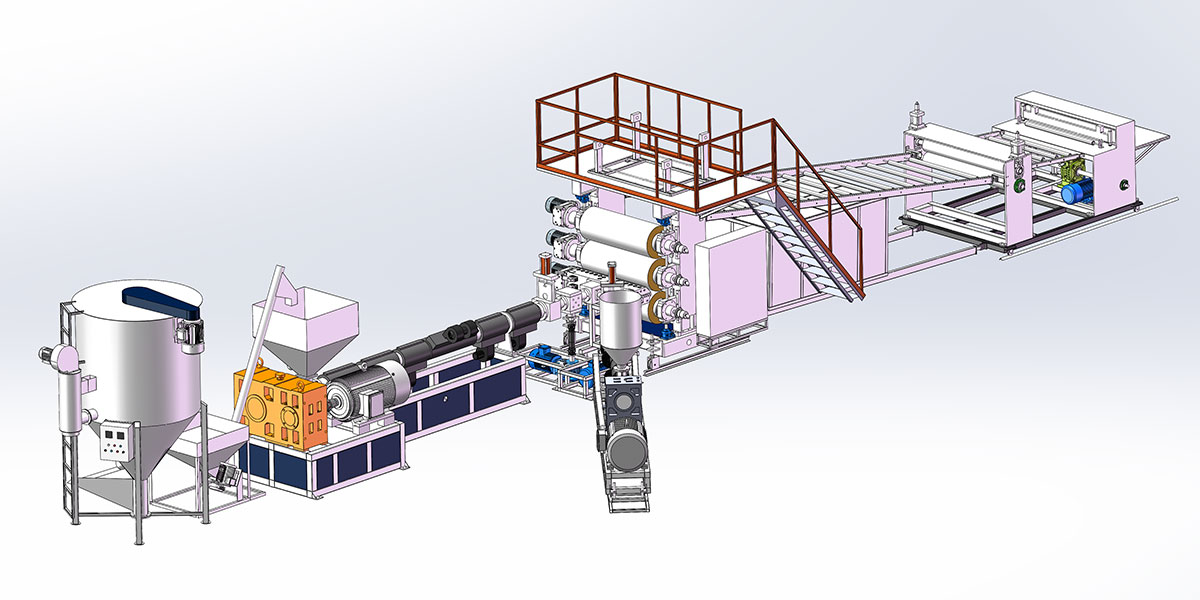

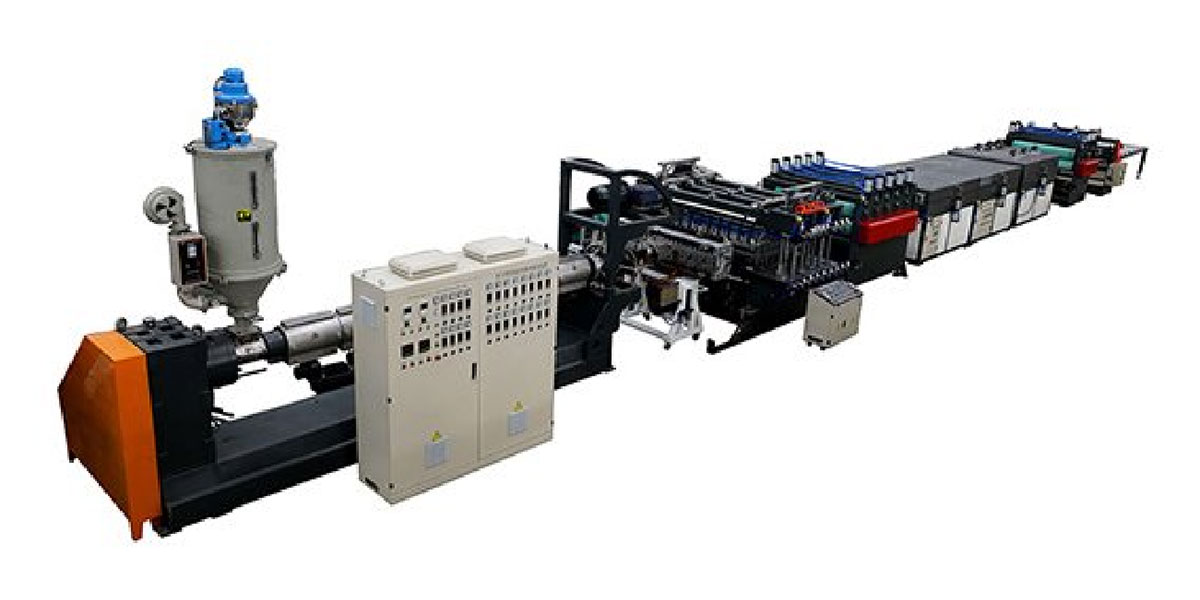

Transparent PVC Soft Sheet Extrusion Line Equipment

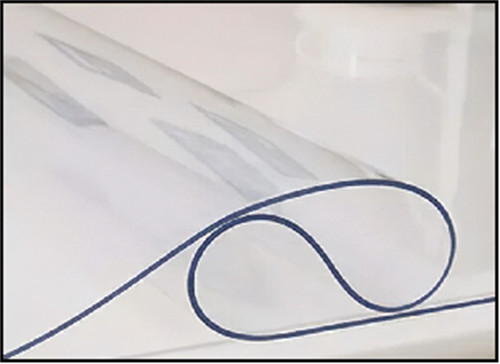

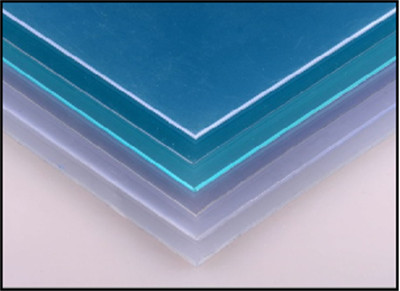

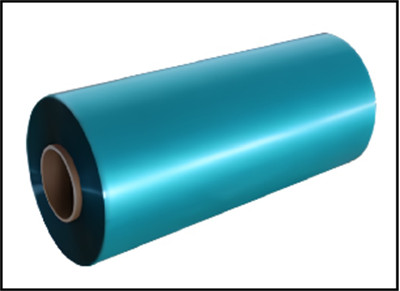

PVC transparent soft board soft door curtain is a replacement product of traditional cotton door curtain. It has the characteristics of softness, transparency, insulation, safety, green, environmental protection, acid and alkali resistance, no peculiar smell, and easy cleaning. Anti-ultraviolet, sound insulation, table mat, lighting, industrial vibration reduction, safety warning, floor and wall, utensil surface protection and paint film protection, can be used for refrigeration, food, printing, textile, electronics, instrumentation, pharmaceutical, storage, shopping malls, etc. place. It has a good effect on the insulation of live workplaces and the shielding of harmful arc light.

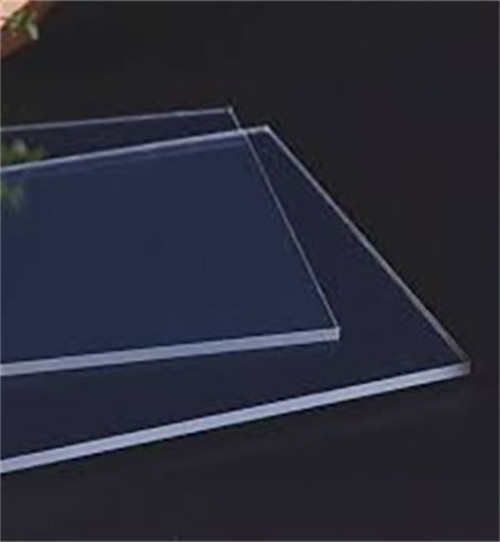

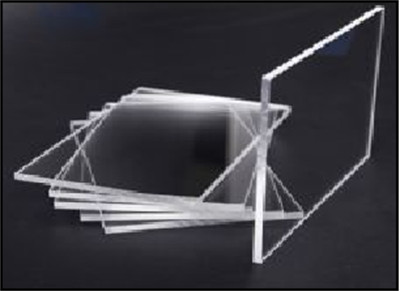

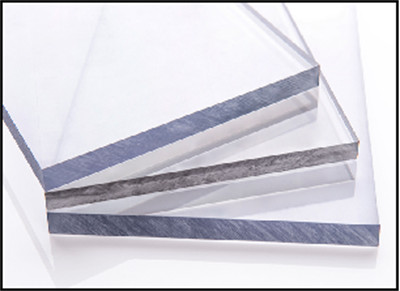

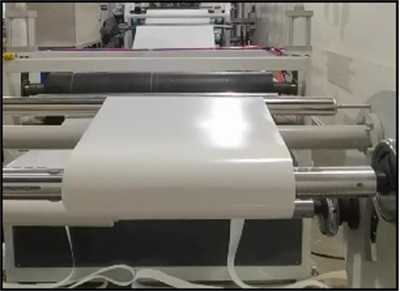

Transparent PVC Rigid Sheet Extrusion Line

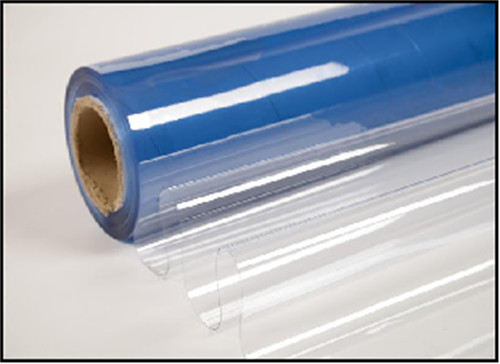

PVC extruded transparent sheet has the characteristics of flame retardant self-extinguishing, high quality and low price, high transparency, good surface gloss, less crystal point, small water pattern, strong impact resistance and easy forming, etc. It is widely used in various tools and toys. , Blister, folding box, packaging, etc. in electronics, food, medicine, clothing and other industries.

|

Main Technical Specification |

||

|

Extruder Specification |

LSJ120/25-1400 |

LSJZ80/1 56-1 220 |

|

ProauctsWidth |

1400mm |

1220mm |

|

ProductsThickness |

0.2-2mm |

0.2-3mm |

|

Main MotorPower |

90KW |

75KW |

|

Extrusion Output |

350KG/H |

300KG/H |

Note:The specifications are subject to change without prior notice.

]]>

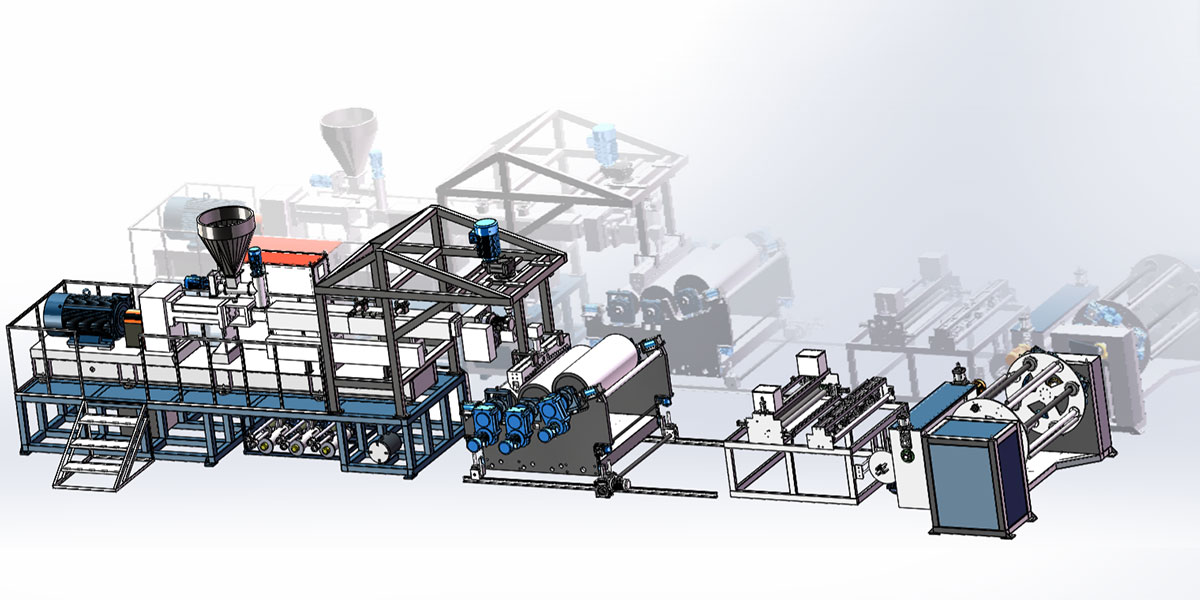

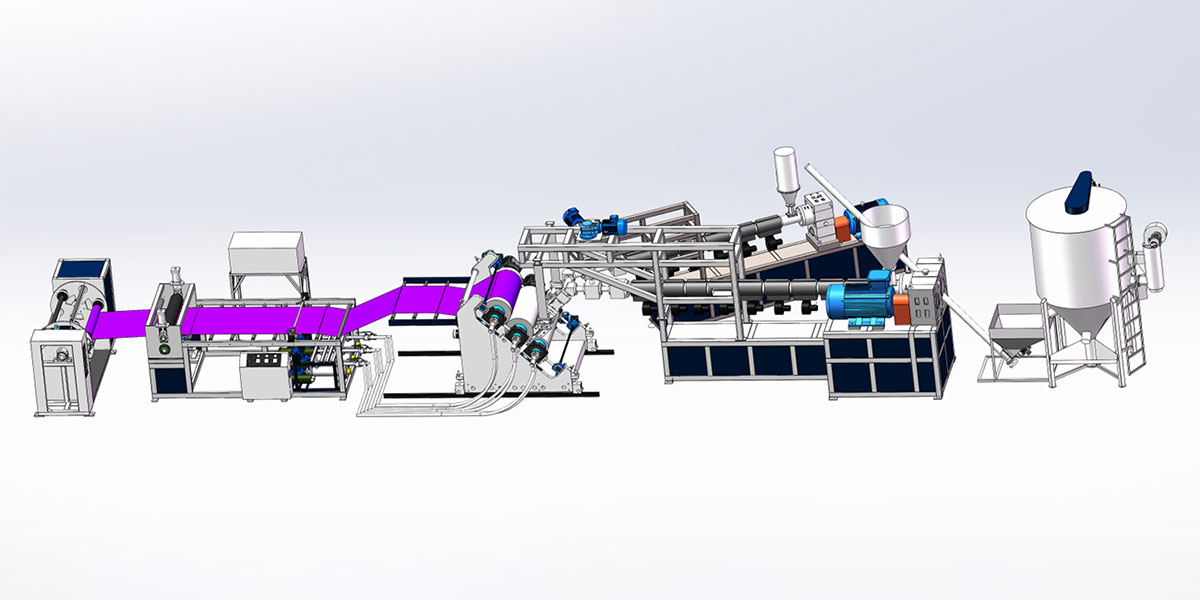

Dry-free crystallization and exhaust type-co-rotating parallel twin-screw sheet extrusion production line: It has the characteristics of low energy consumption, simple process, and convenient equipment use and maintenance. The flexible combination of the screw structure reduces the viscosity drop of the PET resin, the symmetrical roller improves the cooling efficiency while improving the production capacity and the quality of the sheet, and multiple sets of feeding devices reasonably control the ratio of new material, returned material, color masterbatch, etc. , the produced sheets can be used in the fields of blister printing and packaging.

PET Single-layer/Multi-layer Sheet Extrusion Production Line Equipment

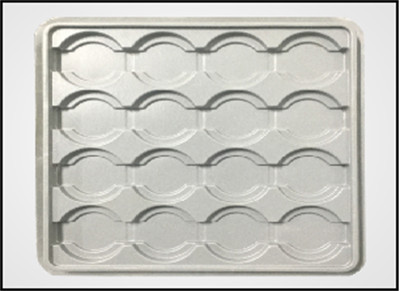

PET sheet is widely used in the outer packaging of cosmetics, medicines, tobacco and alcohol, etc.; the outer packaging of general commodities and the fields of stationery, pendants, advertising, posters, various cards, elevators, etc.; electronic trays, blister trays for seedling trays box.

APET Single-layer/Multi-layer Sheet Extrusion Production Line Equipment

APET has the characteristics of heat shrinkable plastic film packaging: it is transparent to the body; the packaging is tightly bundled, and has good anti-scattering properties; It is often used in the packaging of convenience food, beverages, electronic appliances, metal products, etc., especially shrink labels are the most important application areas.

PETG Single-layer/Multi-layer Sheet Extrusion Production Line Equipment

PETG, also known as low temperature PET, is a new type of environmentally friendly packaging material with high gloss, high transparency, excellent barrier properties and self-adhesion. Can be used for glue bonding, high frequency processing.

|

LSJ single screw extruder model |

LTP co-directional flat twin extruder model |

|||

| Main Technical Specification | Main Technical Specification | |||

| Specification |

Single layer extrusion |

Multilayer extrusion |

Single layer extrusion |

Multilayer extrusion |

| Products Width |

800-1400mm |

800-1400mm |

800-1400mm |

800-1400mm |

|

Products Thickness |

0.2-2.5mm |

0.15-3mm |

0.2-2.5mm |

0.15-3mm |

| Extruder Specification |

LSJZ130/38 |

LSJ130/38&LSJ75/38 |

LTP75/40 |

LTP75/40 |

| Main MotorPower |

185KW |

185KW&75KW |

132KW |

132KW&160KW |

|

Extrusion Output |

600KG/H |

750KG/H |

650KG/H |

950KG/H |

| Note:The specifications are subject to change without prior notice. | ||||

ABS luggage/blister sheet Extrusion Production Line Equipment

The advantages of the suitcase made of ABS are that it is relatively hard, not easy to be deformed by pressure, the shell has high strength, is not easy to be damaged, and can effectively protect the contents. The impact resistance of PC is 40% higher than that of ABS. After the ABS trolley case is impacted, the surface of the case will appear creases or even burst directly, while the dent of the PC case can gradually bounce back to the prototype after receiving the impact.

Combining the advantages and disadvantages of the two materials, it is composite extruded, which maximizes the service life of the luggage.

| Main Technical Specification | |||

| Suitable material |

ABS、PC |

ABS、PC |

|

| Products width |

1400mm |

1800mm |

|

| Products thickness |

1 3.5 mm |

1 4mm |

|

| Extrudermodel |

LSJ120/38&LSJ75/38 |

LSJ150/38&LSJ90/38 |

|

| Designed capacity |

450Kg/h |

550Kg/h |

|

| Note:The specifications are subject to change without prior notice. | |||

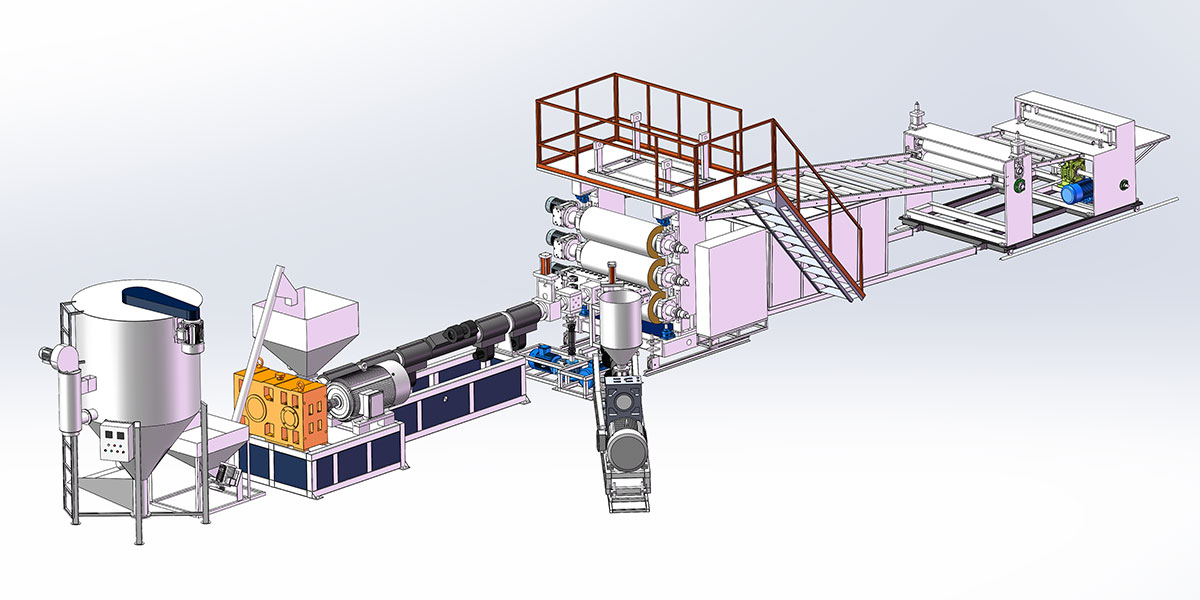

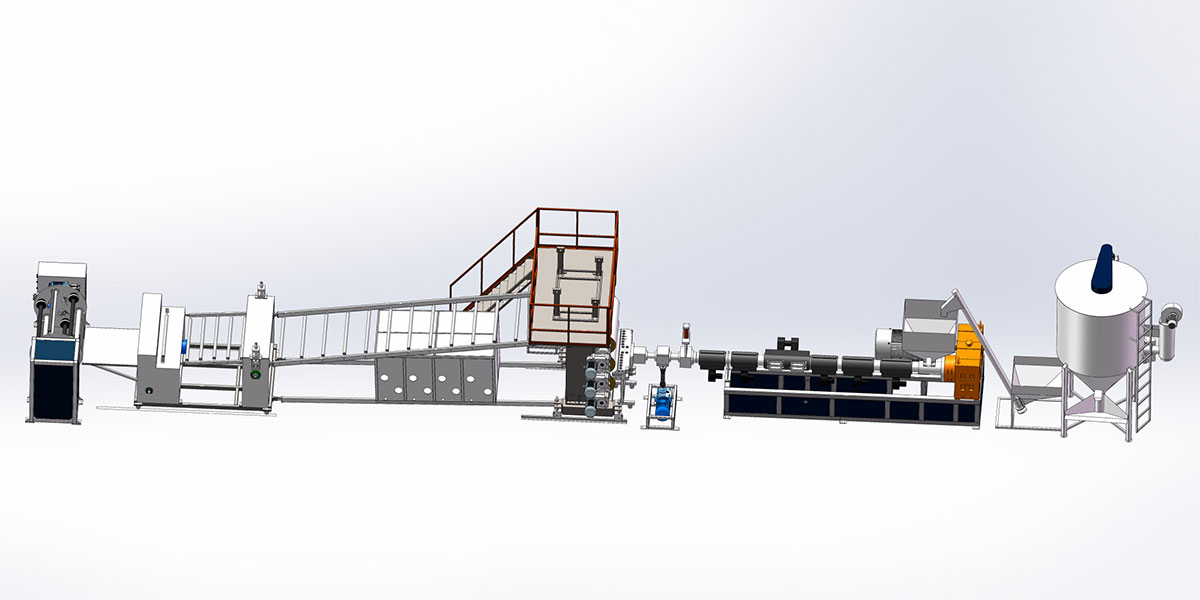

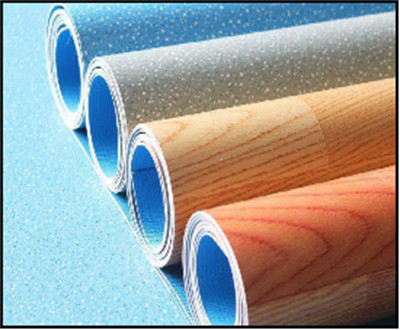

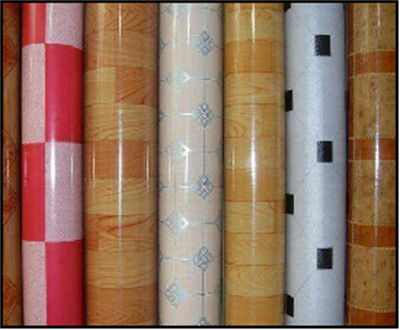

PVC Wide Floor Leather, Waterproof Rolls Extrusion Production Line Equipment

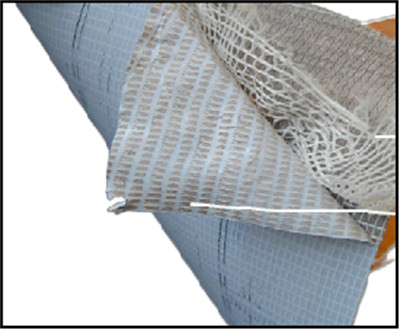

Mainly used in the production of PVC floor leather products and PVC waterproof Rolls products. PVC floor leather has the properties of wear resistance, corrosion resistance, anti-skid, anti-seepage and flame retardant, and is widely used in locomotives, hotels, hotels, entertainment halls, exhibition halls, and families. PVC waterproofing membrane can be applied to various roof waterproofing, basements, reservoirs, dams, highway tunnels, railway tunnels, air raid shelters, grain depots, garbage plants, wastewater treatment and other building waterproofing projects in the industrial and construction industries.

Can be configured with different equipment components according to customer requirements to produce single-layer and multi-layer composite products; unwinding devices can also be added to produce internal reinforced products or surface composite non-woven fabrics, PVC decorative films and other products .

|

Main Technical Specification |

||

| Specification |

Double Layers |

Three Layers |

| Products Width |

1500-2000mm |

2000-3000mm |

| ProductsThickness |

0.7-3.5mm |

0.7-3.5mm |

| ExtmderSpedfication |

LSJZ80/156&LSJZ92/188 |

LSJZ65/132&LSJZ92/188&LSJZ80/156 |

|

Main Motor Power |

55kw&90kw |

37kw&90kw&55kw |

| ExtrusionOutput |

450-500kg/h |

600-750kg/h |

| Note:The specifications are subject to change without prior notice. | ||

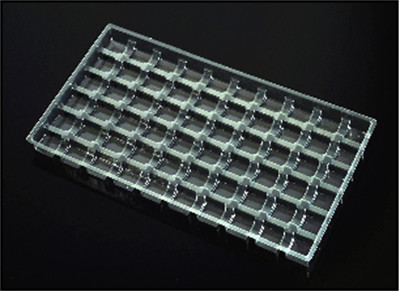

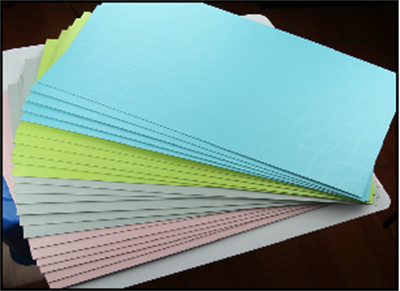

PP,PS Single-layer/Multi-layer Co-extrusion Blister Sheet Extrusion Production Line Equipment

Sheets are divided into transparent sheets, frosted sheets (coarse sand, fine sand), two-color sheets, etc. Wide range of uses, can be used in the food industry and packaging industry after plastic forming. For example: milk tea cups, fast food boxes and other food packaging; pharmaceutical packaging; cosmetic packaging; electronic products and other packaging.

PP, PS Two-color Co-extrusion Blister Sheet Extrusion Production Line Equipment

PP has good heat resistance and does not change without external force; PS has excellent insulation performance and high light transmittance. Therefore, the use of PP and PS co-extruded sheets improves the advantages of both. Mainly used with some blister products, milk tea cup lids, decorative pendants, etc.

|

Main Technical Specification |

||

|

Model |

LSJ120/38 |

LSJ120/38&LSJ80/38 |

| Suitable material |

PP、PS |

PP&PS |

| Products width |

800mm |

800mm |

|

Productsthickness |

0.2 - 2 m m |

0.2-2mm |

| Max extrusion capacity |

450kg/h |

550kg/h |

| Note:The specifications are subject to change without prior notice. | ||

PC optical sheet extrusion production line equipment

PC is an amorphous thermoplastic resin with excellent comprehensive properties. It has excellent electrical insulation, elongation, dimensional stability and chemical resistance, high strength, heat resistance and cold resistance; it also has self-extinguishing, Flame retardant, non-toxic, colorable and other advantages. Mainly used in the automotive industry; membrane switches in the electronics and electrical industries; LCD screens in computers, mobile phones, and business communications; sunglasses, sun hats, mirrors, protective masks; special printing; pharmaceutical packaging and other fields.

PMMA optical sheet extrusion production line equipment

Can be configured with different equipment components according to customer requirements to produce single-layer and multi-layer composite products; unwinding devices can also be added to produce internal reinforced products or surface composite non-woven fabrics, PVC decorative films and other products .Optical grade PMMA is a flame retardant, self-extinguishing material. It has transparency, soft light, clear vision, good surface decoration effect and color rendering effect for printability and sprayability; it has excellent high temperature performance, can be thermoformed or machined, and has high wear resistance and corrosion resistance

|

Main Technical Specification |

||

|

Model |

LSJ100/36 |

LSJ120/36 |

|

Suitable material |

PC、PMMA |

PC、PMMA |

|

Products width |

1000 mm |

1 200mm |

|

Products thickness |

0.3-3.0mm |

0.2-2m m |

|

Max extrusion capacity |

300kg/h |

450kg/h |

| Note:The specifications are subject to change without prior notice. | ||

PMMA (acrylic/GPPS) Sheet/Plate extrusion production line equipment

Widely used in instruments, instrument parts, lamps, decoration, building materials, aircraft, auto parts, medical equipment, craft products, electrical insulation materials, specimens, signs and various light industry, culture and education, daily necessities, etc.

PC solid sheet/plate extrusion production line equipment

Widely used in gardens, amusement places, exotic decorations and pavilions of resting places; interior and exterior decorations of commercial buildings, curtain walls of modern urban buildings; aviation transparent containers, front windshields of motorcycles, planes, trains, ships, cars, steamboats, etc.; telephone booths , advertising road signs, light box advertising display exhibition layout; highway and urban elevated road barriers.

| Main Technical Specification | |||

| Suitable material |

PC、PMMA、GPPS |

PC、PMMA、GPPS |

|

| Productswidth |

2500mm |

1 300mm |

|

| Products thickness |

2-1 5mm |

1 -1 0mm |

|

| Extrudermodel |

LSJ150/38 &LSJ90/35 |

LSJ120/38 & LSJ45/30 |

|

| Max extrusion capacity |

750Kg/h |

480Kg/h |

|

| Note:The specifications are subject to change without prior notice. | |||

PLA Degradable Sheet/Rolls Sheet Extrusion Production Line Equipment

Lactic acid, the main component of PLA, is mostly prepared by fermentation of starch, and the process and technology are mature. It is a colorless, smooth hard plastic with high strength and high modulus. Its mechanical properties are similar to PS, and its tensile and flexural modulus are higher than HDPE, but its toughness is poor. It is suitable for various processing processes such as injection molding, blow molding, thermoforming, extrusion, casting, melt spinning and electrospinning. Mainly used for packaging and fibers. also be used as engineering plastics in machinery, chemical and other equipment, and is widely used in drainage boards.

PBAT Degradable Sheet/Rolls Sheet Extrusion Production Line Equipment

PBAT is an aliphatic-aromatic copolyester with low crystallization rate, flexible aliphatic chain and rigid aromatic ring in the molecular chain, excellent mechanical properties and can be naturally degraded. Widely used in plastic film, film bag packaging and other fields, it is one of the fastest growing and most widely used degradable plastic varieties.

PBS Degradable Sheet/Rolls Sheet Extrusion Production Line Equipment

PBS (direct esterification method) has a high melting point, can withstand a high temperature of 100 ° C with a little modification, has excellent degradation performance, and can be biodegraded under natural conditions. Moreover, it is easy to process, has good heat resistance, excellent comprehensive mechanical properties, and has a wide range of uses. In the medical field (such as artificial cartilage, sutures, stents), etc.

| Main Technical Specification | |||

|

Model |

LSJ single screw extruder model |

LTP co-directional flat twin extruder model |

|

| Suitable material |

PLA, PBAT, PBS |

PLA, PBAT, PBS |

PLA, PBAT, PBS |

| Productswidth |

650-1 350mm |

650-1 350mm |

650-1 350mm |

| Products thickness |

0.1 5-3mm |

0.1 5-3mm |

0.1 5-3mm |

| Extrudermodel |

LSJ 120/3 5 |

LTP75/40 |

LTP85/40 |

| Main MotorPower |

132KW |

132KW |

160KW |

| Designed capacity |

200Kg/h |

2500Kg/h |

300Kg/h |

| Note:Thespecificationsaresubjectto change without prior notice. | |||

ABS thick plate extrusion line

ABS thick plates are widely used in home appliances, electronics, packaging, medical equipment and other fields.

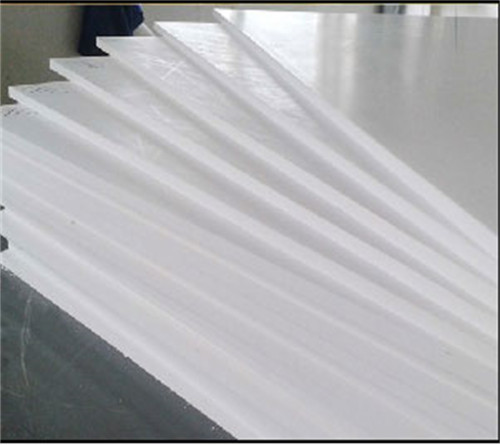

PVC thick plate extrusion line

Rigid PVC thick plates are widely used in chemical, petroleum, electroplating, water purification and treatment equipment, environmental protection equipment, mining, pharmaceutical electronics, communications, anti-corrosion containers, equipment and electrical shields, light boxes, advertising decoration and other industries.

PP thick plate extrusion line

PP thick plate can be widely used in chemical industry, food industry, anti-corrosion industry, purification industry and environmental protection equipment production industry.

PE thick plate extrusion line

Polyethylene (PE) sheets are widely used in chemical, electric power and other industries. HDPE board can also be used as engineering plastics in machinery, chemical and other equipment, and is widely used in drainage boards.

| Main Technical Specification | ||||

|

Model |

LSJ120 |

LSJ150 |

LSJ170 |

LSJZ80/156 |

| Suitable material |

PP、PE、ABS |

PP、PE、ABS |

PP、PES ABS |

PVC |

| Products width |

1 220mm |

1 800mm |

2000mm |

1 220mm |

| Products thickness |

3-30m m |

3-30mm |

3-30mm |

3-30mm |

| Extruder mod el |

LSJ120/35 |

LSJ150/35 |

LSJ 180/3 5 |

LSJZ80/156 |

| Designed capacity |

380Kg/h |

550Kg/h |

750kg/h |

480Kg/h |

| Note:The specifications are subject to change without prior notice. | ||||

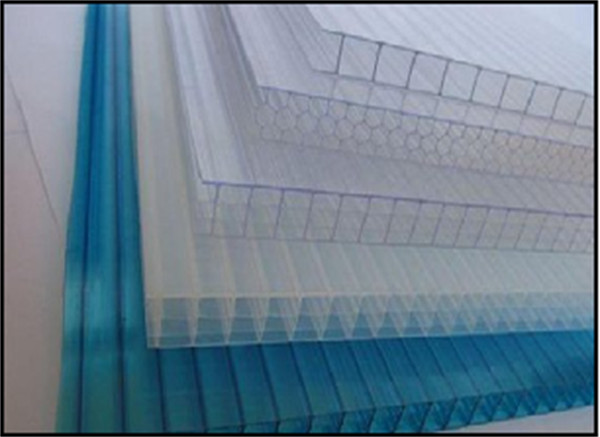

PC Hollow Lattice Board Extrusion Production Line Equipment

PC hollow board has the characteristics of high transparency, light weight, impact resistance, sound insulation, heat insulation, flame retardancy, anti-aging, etc., but it is not resistant to acid and alkali. It is widely used in lighting ceilings and sunshade canopies in commerce, factories, stadiums, agricultural greenhouses, aquaculture and flower greenhouses, as well as public facilities such as telephone booths, newsstands, stations, highway sound insulation, and advertising decoration.

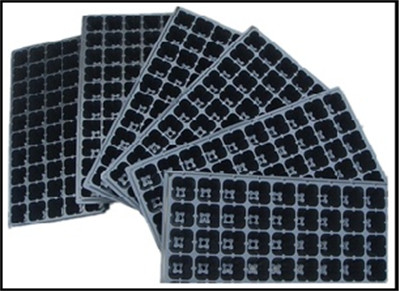

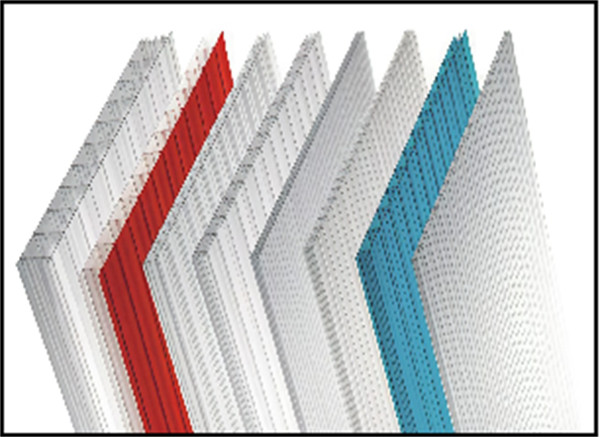

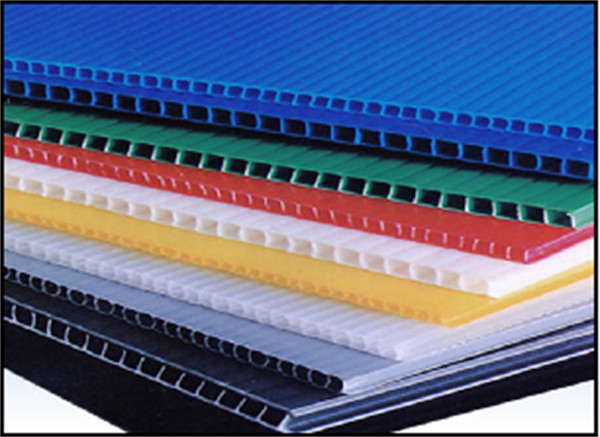

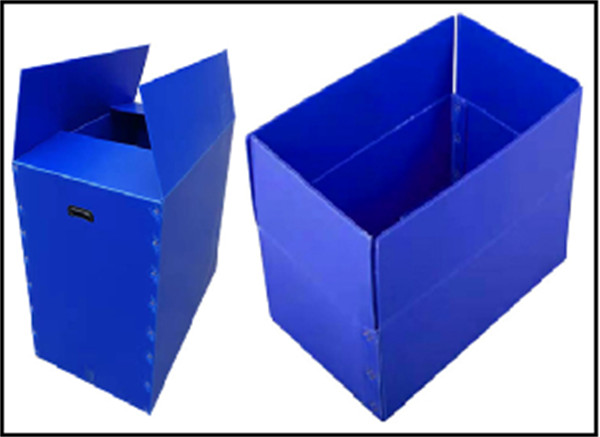

PP Hollow Lattice Board Extrusion Production Line Equipment

PP hollow board has the properties of non-toxic, non-polluting, corrosion-resistant, waterproof and shock-proof. It is widely used in electronic components packaging turnover box, plastic parts turnover box, box partition knife card, anti-static hollow board turnover box, conductive hollow board turnover box, luggage liner, luggage pad, and partition.

| Main Technical Specification: | ||||

| Model |

PP Hollow Lattice Board |

PC Hollow Lattice Board |

||

| Suitable material |

PP |

PC |

||

| Products width |

2100mm |

1 220mm |

2100mm |

1400mm |

| Products thickness |

2-9mm |

2-9mm |

2-40mm |

2-40mm |

| Extrudermodel |

LSJ150/36 |

LSJ100/34 |

LSJ120/38&LSJ45/30 | LSJ100/38&LSJ45/30 |

| Main MotorPower |

160KW |

110KW |

185KW&22KW |

132KW&22KW |

| Designed capacity |

450KG/H |

250KG/H |

450KG/H |

350KG/H |

| lote:The specifications are subjectto change without prior notice. | ||||